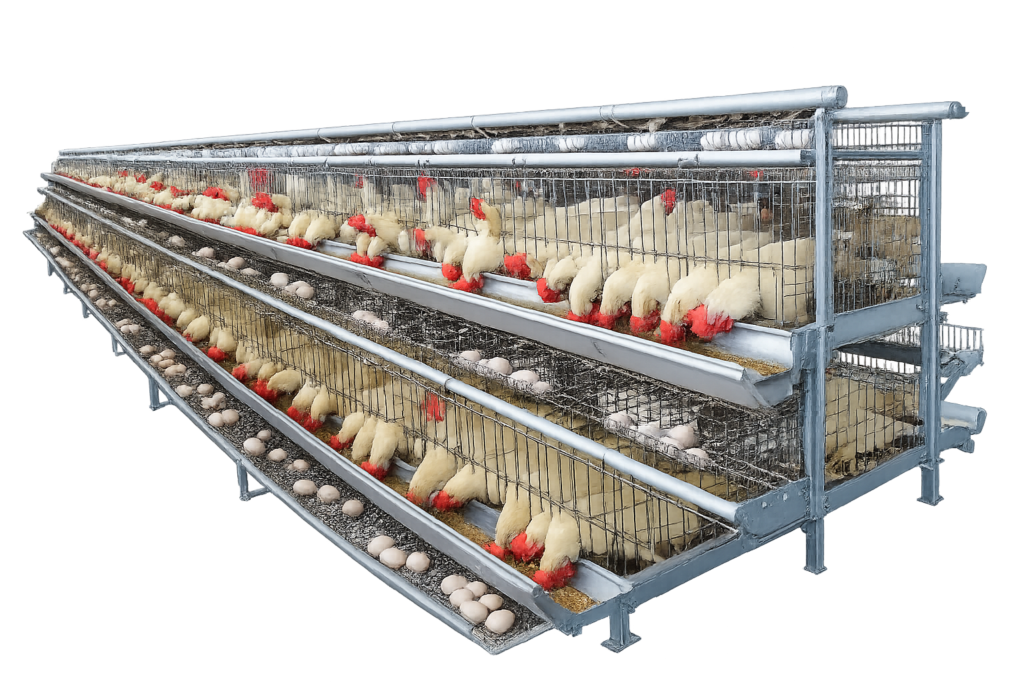

Our Products

Ventilation System

Zero Risk

Premium Quality

Quick Start

Why Choose Us

Why Choose Asian Poultry Tech India Pvt. Ltd.?

Asian Poultry Tech India Pvt. Ltd. stands out as a trusted partner in poultry equipment manufacturing. Our feeding systems are engineered with a focus on innovation, quality, and customer satisfaction. We are committed to delivering products that not only meet but exceed industry standards, helping you achieve excellence in poultry management.

Industry-Focused Expertise

Asian Poultry Tech India Pvt. Ltd. is a dedicated poultry equipment and solutions provider focused on modernizing poultry farms with advanced technologies tailored to broiler, breeder, and layer operations.

Comprehensive Farm Solutions

Integrated feeding, ventilation, climate control, and heating systems ensure efficient feed use, optimal conditions, healthier birds, and improved overall farm productivity.

Focus on Quality, Innovation & Performance

The company emphasizes quality craftsmanship and innovation in its products and systems, aiming to meet the evolving needs of modern poultry farming.

Trusted by Farmers Across India

Asian Poultry Tech is reportedly trusted by a large number of farmers, reflecting regional adoption and confidence in their solutions.

Our Ventilation System

Ensuring Optimal Air Quality for Healthy Poultry

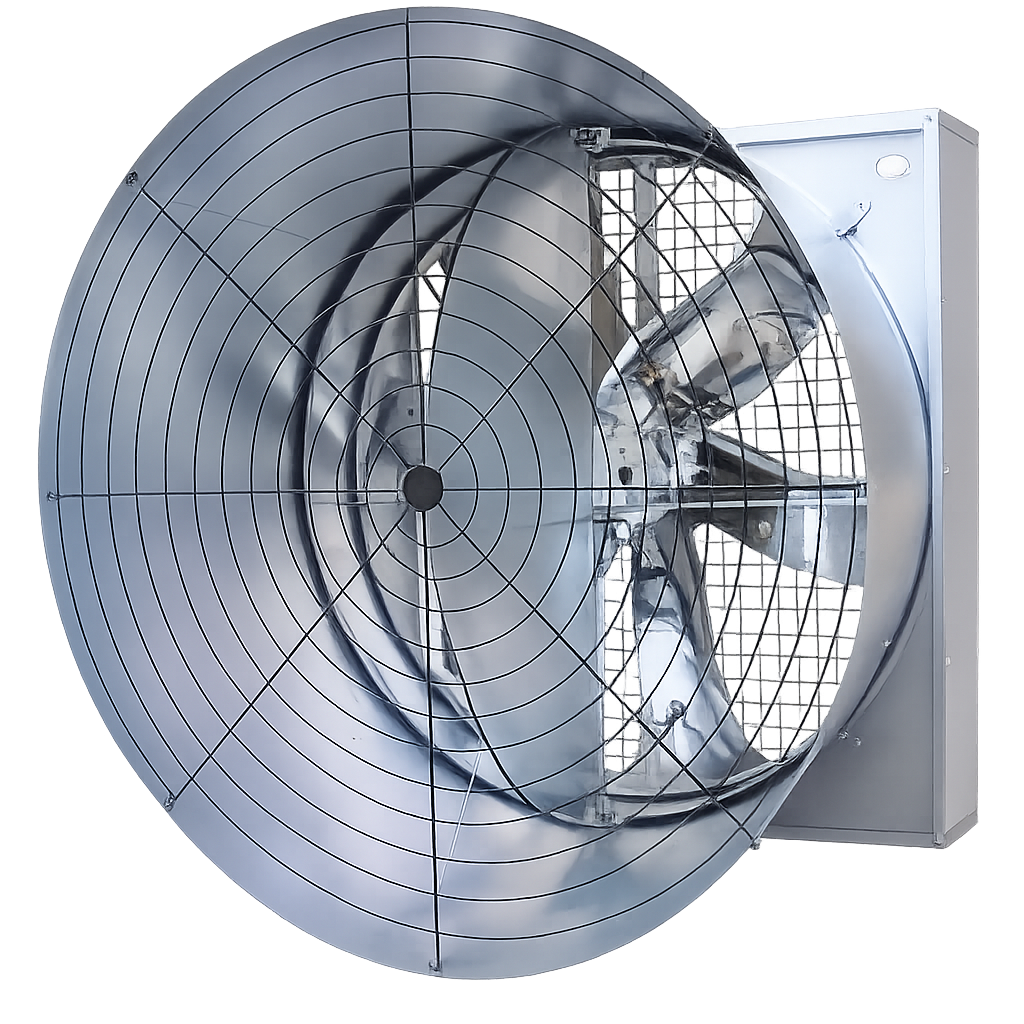

Cone Fans

- High-Efficiency Airflow

- Energy-Saving Performance

- Wide Coverage Design

- Durable & Weather-Resistant

- Easy Installation & Maintenance

About Cone Fans

Key Features

1.Superior Airflow and Efficiency:

- High-Performance Air Movement: The cone fans from Asian Poultry Tech are designed to move large volumes of air, ensuring that fresh air circulates effectively throughout the poultry house. This high airflow capability is essential for maintaining a stable climate, reducing humidity, and preventing the buildup of harmful gases like ammonia.

- Aerodynamic Cone Design: The unique cone-shaped housing of these fans enhances the efficiency of air movement by minimizing resistance and optimizing the direction of airflow. This design maximizes the fan’s performance while reducing the energy required to achieve the desired ventilation levels.

2. Energy-Efficient Operation:

- Low Power Consumption: Equipped with high-efficiency motors, the cone fans are designed to deliver powerful ventilation while consuming minimal electricity. This energy-efficient operation helps reduce the overall operational costs of poultry farms, making these fans a cost-effective solution for long-term use.

- Sustainable Ventilation: By utilizing less energy without compromising on performance, the cone fans contribute to a more sustainable farming operation. Their eco-friendly design aligns with modern agricultural practices that prioritize energy conservation and environmental responsibility.

3. Durable and Long-Lasting Construction:

- Obust Materials: Built with high-quality, corrosion-resistant materials, the cone fans are designed to withstand the harsh conditions typical of poultry environments. Their durable construction ensures that the fans remain operational and effective over many years, even in challenging climates.

- Weather-Resistant Coatings: The fans are treated with weather-resistant coatings that protect them from rust, corrosion, and other forms of wear and tear. This added protection enhances the longevity of the fans, reducing the need for frequent replacements.

4. Cost-Effective Ventilation:

- The energy-efficient design of the cone fans helps reduce electricity costs, while their durable construction minimizes the need for repairs and replacements. These factors make the fans a cost-effective solution for long-term ventilation needs in poultry farming.

5. Improved Farm Efficiency:

- By ensuring optimal airflow and temperature control, the cone fans contribute to a more efficient farming operation. Birds are more comfortable and less stressed, which can lead to improved performance and profitability for the farm.

About Box Fans

Box Fans

- Powerful Air Circulation

- Energy-Efficient Performance

- Improved Bird Comfort

- Noise-Optimized Operation

- Integration With Automated Controls

Key Features

1.Superior Airflow and Efficiency:

- High Volume Air Movement: Asian Poultry Tech’s box fans are specifically designed to move large volumes of air efficiently, ensuring consistent and even ventilation throughout the poultry house. This robust airflow helps to eliminate hotspots, reduce humidity, and maintain optimal temperature levels, creating a stable environment for poultry.

- Optimized Blade Design: The fans feature aerodynamically designed blades that maximize airflow while minimizing energy consumption. This design ensures that the fans operate at peak efficiency, providing effective ventilation with lower operational costs.

2. Durable and Weather-Resistant Construction:

- High-Quality Materials: Built from premium-grade materials, including corrosion-resistant metal and high-strength polymers, the box fans are designed to withstand the demanding conditions of poultry houses. This durability ensures long-lasting performance, even in challenging environments.

- Protective Coatings: The fans are coated with weather-resistant finishes that protect them from rust, corrosion, and wear, extending their lifespan and reducing the need for frequent replacements.

3. Easy Installation and Maintenance:

- Simple Setup: The box fans are designed for easy installation, with clear instructions and support provided by Asian Poultry Tech’s technical team. Their versatile design allows them to be mounted in various positions, adapting to the specific layout of any poultry house.

- Low Maintenance Requirements: These fans are engineered to require minimal maintenance, thanks to their durable construction and efficient design. Routine cleaning and occasional inspections are typically all that’s needed to keep them running smoothly, reducing downtime and maintenance costs.

4. Increased Farm Efficiency:

- By ensuring optimal airflow and temperature control, the box fans contribute to a more efficient farming operation. Birds are more comfortable, which can lead to better growth rates, improved feed conversion, and higher egg production, ultimately boosting the farm’s profitability.

5. Cost-Effective Ventilation:

- The energy-efficient design of the box fans helps lower electricity costs, while their durability reduces the need for frequent replacements. These factors make the fans a cost-effective solution for long-term ventilation needs.

Tunnel Inlet

Optimal Air Distribution: The tunnel inlet systems by Asian Poultry Tech are designed to work in tandem with exhaust fans, directing fresh air into the poultry house in a controlled and uniform manner. This ensures that the entire space receives adequate ventilation, preventing the formation of hotspots or cold zones.

Precision Control: The inlets are adjustable, allowing for precise control of the airflow direction and volume. This adaptability is key to maintaining an ideal environment, especially in large-scale operations.

- Core Component of Tunnel Ventilation

- Adjustable Airflow Control

- Enhanced Air Distribution

- Improves Temperature Management

- Energy-Efficient Design

About Tunnel Inlet

Key Features

1. Innovative Air Inlet Design:

- Optimal Air Distribution: The tunnel inlet systems by Asian Poultry Tech are designed to work in tandem with exhaust fans, directing fresh air into the poultry house in a controlled and uniform manner. This ensures that the entire space receives adequate ventilation, preventing the formation of hotspots or cold zones.

- Precision Control: The inlets are adjustable, allowing for precise control of the airflow direction and volume. This adaptability is key to maintaining an ideal environment, especially in large-scale operations.

2. Energy-Efficient Operation:

- Reduced Power Consumption: The tunnel inlet systems are designed to complement the efficiency of the overall ventilation system, reducing the load on exhaust fans and cooling systems. This synergy leads to lower energy usage and more cost-effective operation.

- Automatic Inlet Adjustment: Some models feature automated adjustment mechanisms that respond to changes in external weather conditions, ensuring consistent airflow without the need for constant manual intervention.

3. Durable and Long-Lasting Construction:

- Sturdy Construction: The inlets are made from durable, weather-resistant materials that can withstand the rigors of poultry house environments. Their robust design ensures a long service life with minimal maintenance needs.

- Simple Installation: Asian Poultry Tech’s tunnel inlet systems are designed for easy installation, with clear instructions and minimal disruption to ongoing operations. This allows for quick integration into existing poultry houses.

4. Enhanced Bird Health and Productivity:

- He combination of efficient exhaust fans, cooling systems, and tunnel inlet systems creates an optimal living environment for poultry, reducing stress and the incidence of respiratory issues. This leads to healthier birds and improved productivity in terms of growth rates, feed conversion, and egg production.

5. Cost Savings and Energy Efficiency:

- By utilizing energy-efficient components and smart climate control integration, these systems help reduce operational costs while maintaining the ideal environment for poultry. The durability and low maintenance requirements further contribute to long-term savings.

About Cooling Pads

Cooling Pads

High Cooling Efficiency: The Honey Bee Cooling Pads are designed using high-density cellulose material with a unique honeycomb structure. This design maximizes the surface area for water evaporation, which effectively lowers the temperature inside poultry houses, creating a cooler and more comfortable environment for the birds.

Optimal Water Retention: The pads are engineered to retain water for a longer period, allowing for sustained cooling even in extremely hot climates. This ensures that the cooling effect is consistent, reducing the risk of heat stress among poultry.

- Efficient Evaporative Cooling

- Enhanced Airflow & Comfort

- Improved Growth & Production

- Reduced Heat Stress

- Energy-Efficient Solution

Key Features

1. Innovative Cooling Technology:

- High Cooling Efficiency: The Honey Bee Cooling Pads are designed using high-density cellulose material with a unique honeycomb structure. This design maximizes the surface area for water evaporation, which effectively lowers the temperature inside poultry houses, creating a cooler and more comfortable environment for the birds.

- Optimal Water Retention: The pads are engineered to retain water for a longer period, allowing for sustained cooling even in extremely hot climates. This ensures that the cooling effect is consistent, reducing the risk of heat stress among poultry.

2. Durable and Long-Lasting Construction:

- Premium Quality Materials: Constructed from high-grade cellulose and treated with anti-rot and anti-mold agents, the Honey Bee Cooling Pads are designed to resist degradation and maintain their effectiveness over time. This durability ensures a long service life, even in harsh conditions.

- Weather-Resistant Design: The pads are built to withstand the environmental challenges often faced in poultry farming, such as high humidity, extreme temperatures, and exposure to dust and debris.

3. Increased Farm Productivity:

- By ensuring a stable and comfortable environment, the Honey Bee Cooling Pads contribute to improved productivity in poultry operations. Birds are more likely to eat and grow efficiently when they are kept at an ideal temperature, leading to better performance and profitability.

4. Eco-Friendly and Energy-Efficient:

- Low Energy Consumption: The Honey Bee Cooling Pads operate using minimal energy, making them an environmentally friendly option for poultry farmers looking to reduce their carbon footprint. They work efficiently with existing ventilation systems, enhancing overall cooling performance without significantly increasing energy costs.

- Sustainable Cooling Solution: By utilizing the natural process of evaporation, these cooling pads offer an eco-friendly alternative to traditional cooling methods that rely on high energy consumption or chemical refrigerants.

5. Easy Installation and Maintenance:

- Installation Process: The Honey Bee Cooling Pads are designed for easy integration with existing poultry house systems. They can be installed quickly and with minimal disruption to ongoing operations, making them a convenient upgrade for any poultry farm.

- Low Maintenance Requirements: These cooling pads are designed for minimal upkeep. The materials used are resistant to clogging and buildup, which means that the pads require only occasional cleaning to maintain peak performance. This reduces maintenance time and costs, allowing farmers to focus on other aspects of farm management.

FAQ

Frequently asked Questions

Everything you need to know about the product.

1. What products and solutions do you offer?

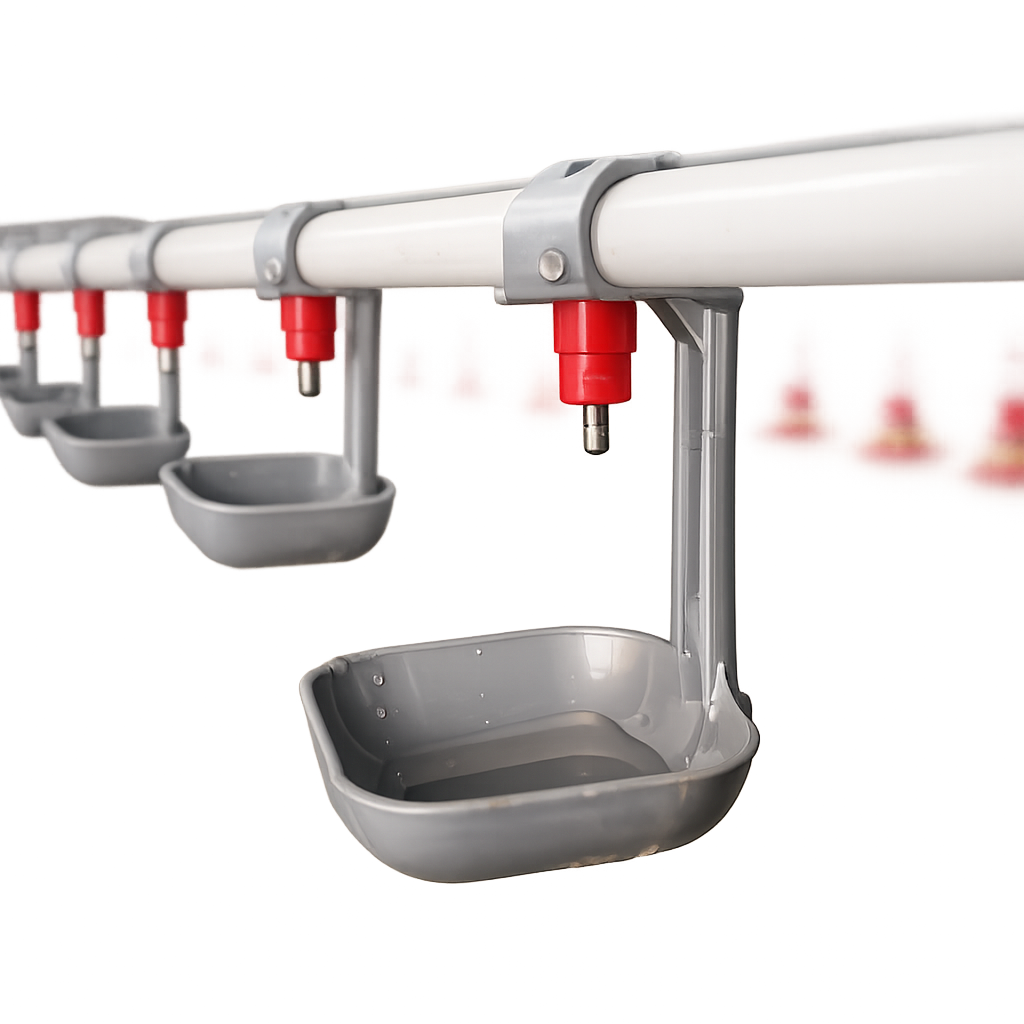

We provide advanced poultry solutions including feeding systems, drinking systems, feed storage, ventilation systems, control automation, open house ventilation, heating solutions, and commercial layer farm technologies — all designed for efficiency and durability.

2. Do you offer turnkey farm setup services?

We provide advanced poultry solutions including feeding systems, drinking systems, feed storage, ventilation systems, control automation, open house ventilation, heating solutions, and commercial layer farm technologies — all designed for efficiency and durability.

3. Are your systems suitable for small and large farms?

We provide advanced poultry solutions including feeding systems, drinking systems, feed storage, ventilation systems, control automation, open house ventilation, heating solutions, and commercial layer farm technologies — all designed for efficiency and durability.

4. What kind of after-sales support do you provide?

We provide advanced poultry solutions including feeding systems, drinking systems, feed storage, ventilation systems, control automation, open house ventilation, heating solutions, and commercial layer farm technologies — all designed for efficiency and durability.

5. Can your systems be automated?

We provide advanced poultry solutions including feeding systems, drinking systems, feed storage, ventilation systems, control automation, open house ventilation, heating solutions, and commercial layer farm technologies — all designed for efficiency and durability.

6. How do your ventilation systems benefit my farm?

We provide advanced poultry solutions including feeding systems, drinking systems, feed storage, ventilation systems, control automation, open house ventilation, heating solutions, and commercial layer farm technologies — all designed for efficiency and durability.

6. How do you provide installation and training?ur ventilation systems benefit my farm?

We provide advanced poultry solutions including feeding systems, drinking systems, feed storage, ventilation systems, control automation, open house ventilation, heating solutions, and commercial layer farm technologies — all designed for efficiency and durability.